Multidisciplinary Geometallurgical Concept Development

Multidisciplinary geometallurgical concept development is a vital process in mining that combines geological, metallurgical, and engineering disciplines to optimize resource extraction and processing. At our company, we specialize in developing comprehensive geometallurgical concepts that enhance project performance and sustainability.

Our development process begins with an in-depth analysis of the geological characteristics of the ore body, including mineralogy, grade distribution, and rock mechanics. We integrate this information with metallurgical data to understand how different ore types respond to various processing techniques. By leveraging advanced modeling and simulation tools, we assess the impact of these variables on recovery rates and overall resource efficiency.

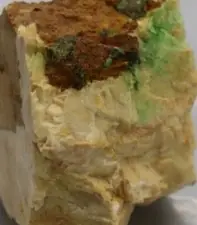

Ore Characterization and Variability Analysis

Ore characterization and variability analysis are essential components of mining operations, providing crucial insights into the properties and behavior of ore bodies. At our company, we specialize in conducting comprehensive analyses that inform resource management and optimize processing strategies.

Our characterization process begins with detailed sampling and testing of ore materials to assess key properties such as mineralogy, grade distribution, and physical characteristics. This data allows us to develop a thorough understanding of the ore body, identifying its unique features and potential challenges in processing.

Geometallurgical Modelling

Geometallurgical modelling is a crucial approach in mining that integrates geological, metallurgical, and operational data to enhance resource extraction and processing strategies. At our company, we specialize in developing comprehensive geometallurgical models that provide insights into the relationship between ore characteristics and processing performance.

The modelling process begins with a thorough characterization of the ore body, including its mineralogy, grade distribution, and physical properties. We gather data from various sources, including laboratory tests, historical performance, and geological surveys, to create a detailed representation of the ore. This data is then integrated into advanced modelling software, enabling us to simulate how different ore types will respond to processing techniques.

Metallurgical Testing Management

Metallurgical testing management is a critical aspect of mining operations, providing essential data that informs the design and optimization of processing strategies. At our company, we specialize in managing comprehensive metallurgical testing programs that deliver reliable results and support informed decision-making.

Our approach to metallurgical testing management begins with a thorough understanding of the specific needs and objectives of each project. We collaborate with clients to identify key testing parameters, such as mineralogical composition, grindability, and recovery rates. This collaborative effort ensures that our testing protocols align with project goals and regulatory requirements.

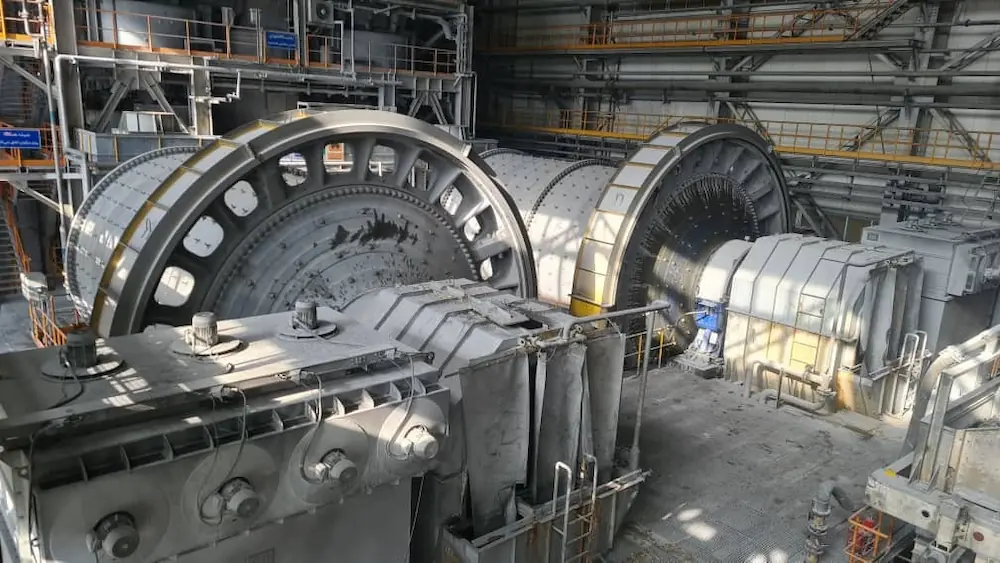

Comminution and Ore Sorting Assessments

Comminution and ore sorting assessments are vital components of mineral processing, aimed at maximizing resource recovery and enhancing operational efficiency. At our company, we specialize in conducting comprehensive assessments that provide valuable insights into the effectiveness of comminution processes and the potential benefits of ore sorting technologies.

Our assessment process begins with a detailed analysis of the ore characteristics, including mineralogy, particle size distribution, and hardness. We collect data through rigorous testing and sampling, which informs the design of optimized comminution circuits tailored to the specific properties of the ore. By utilizing advanced simulation tools, we can model different comminution scenarios, evaluating their impact on recovery rates and overall process efficiency.

Sample Selection and Composite Recipe Preparation

Sample selection and composite recipe preparation are critical processes in mining that significantly influence the reliability of metallurgical testing and the overall success of resource evaluation. At our company, we specialize in meticulously managing these processes to ensure accurate and representative results that guide effective decision-making.

The sample selection process begins with a thorough understanding of the ore body and its characteristics. We collaborate with clients to identify the most relevant sampling locations and methods, ensuring that the samples collected accurately reflect the variability of the ore. This involves taking representative samples from different zones of the deposit, considering factors such as mineralogy, grade, and geological features.

Recovery-Grade Optimization

Recovery-grade optimization is a critical process in mining operations that focuses on maximizing the extraction of valuable minerals while minimizing waste and maintaining product quality. At our company, we specialize in developing strategies that enhance recovery rates and improve the grade of processed ore, ensuring both economic and environmental sustainability.

Our optimization process begins with a comprehensive analysis of the ore body, including its mineralogy, particle size distribution, and metallurgical properties. We employ advanced modeling techniques to simulate various processing scenarios, allowing us to identify the most effective methods for maximizing recovery and grade. This data-driven approach enables us to pinpoint optimal parameters for crushing, grinding, and separation processes.

Process-Design Basis and Circuit Development

Process-design basis and circuit development are essential components of mineral processing that ensure optimal extraction and processing of valuable resources. At our company, we specialize in creating tailored process designs that align with the unique characteristics of each ore body, enhancing operational efficiency and maximizing recovery rates.

The process-design basis begins with a comprehensive evaluation of the ore’s geological and metallurgical properties. We conduct detailed studies on mineralogy, particle size distribution, and chemical composition to inform the design of an effective processing circuit. This foundational knowledge allows us to identify the most suitable processing methods, equipment, and operational parameters.